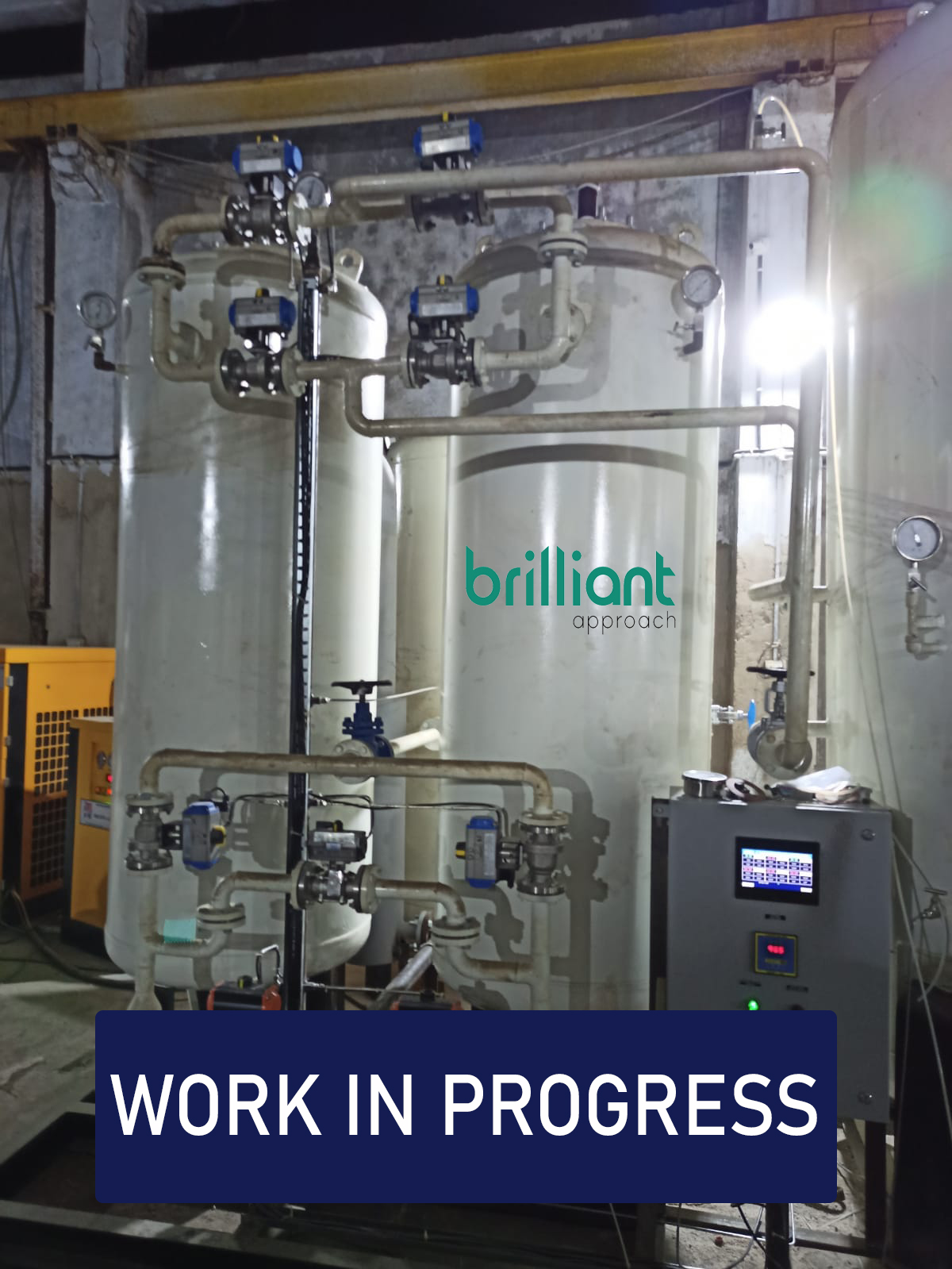

For the Pressure Swing Adsorption (PSA) based process, medical oxygen is produced using distinctive Zeolite Molecular Sieves (ZMS) by absorbing nitrogen from the air. The air in the atmosphere is compressed by an air compressor and cooled by Air Cooler. The condensed moisture shall be drained out automatically from the air received by an automatic drain valve (ADT). The compressed air at constant pressure passed through the Twin tower PSA module packed with molecular sieves. The purity of the gas is up to 96%, which makes it compatible with medical usage in hospitals instantly. We will set up the seamless infrastructure For PSA Oxygen Plant that is cost-effective, time-saving, and incurs annually minimal maintenance cost.

Wherein PSA medical oxygen plant is for the Hospitals, who are planning to get the Online Oxygen Generator installed in by the simplest implementation process for non-interrupted supply. We shall install one Oxygen Generator with a switchover panel. The switchover panel will switch to the current Oxygen Cylinder manifold in case of drop-in purity, pressure, or for maintenance required for the Oxygen Generator.

We manufacture oxygen Generators in compliance with the ASME code & comply with the Indian Pharmacopoeia Oxygen 93% requirement. Oxygen 93% contains not less than 90% oxygen and not over 96%, the remainder consisting mostly of Argon and Nitrogen. Till date thousands of such installations have demonstrated that these are safe for medical purposes.